Basic Info.

| Model NO. | JHXDB-2600 |

| Automatic Grade | Automatic |

| Max. Sheet Size | 900*2500 mm |

| Model | Jhxdb-2600 |

| Mounting Dimensions | 3500*12000+3900*2300 mm |

| Mini. Sheet Size | 300*850 mm |

| Highest Speed | 14000 PCS/H |

| Application Range | a.C.B.Ab Flute 3/5 Layers Corrugated |

| Product Yield | 98% |

| Transport Package | Iron Pallet with Plastic Film |

| Specification | CE |

| Trademark | JIAJIE |

| Origin | Hebei China |

| HS Code | 8441309000 |

| Production Capacity | 6 Sets Per Month |

Product Description

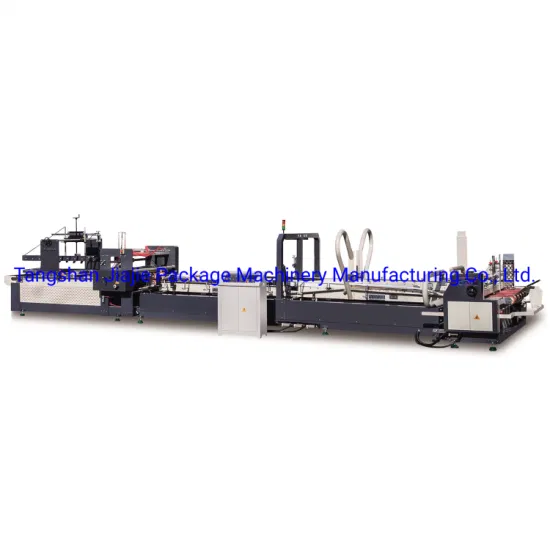

Automatic Folder Gluer and Bundling MachineSpecifications & Carton Size Comparison Tablea)Specifications

| Model | JHX-2600 |

| Max. Carton Size | 1200×2500 mm |

| Mini. Carton Size | 300×850 mm |

| Dimension(mm) | 15000×4000×2300 |

| Installation Area | 4200×17000mm |

| Total Power | 7.9Kw |

| Machine Weight | 6.0t |

| Glue Wheel Size | 25mm/35mm |

| Glue Method | Roller Gluing |

| Speed | 110 m/min |

b)Carton Size Comparison Table

| Model | | JHX-2600 |

| A | Max | 2500mm |

| Min | 640mm |

| B | Max | 1300mm |

| Min | 425mm |

| C | Max | 800mm |

| Min | 190mm |

D | Max | 1200mm |

| Min | 300mm |

Features Of the Machine:Key Features1.Product yield rate can reached 98%.2.Machine parts manufactured by CNC lathe with high precision resulting in little vibration and long service life.3.20mm thickness steel wall dealt with computer control aligning and 5mm thickness square foundation pipe makes the machine strong and solid. 4.The roller are made by 12mm thickness seamless steel pipe which are grinded, balance tested and chromed, ensuring roller vibration less than 0.03 mm.5.Four parts correction together with differential belt correction parts eliminates the fish tail problem effectively. StructureA-Auto Feeding; B-Auto Gluing; C-Auto Folding; D-Auto Stacking And Counting; E--Electrical PartsFeatures by Parts: Feeding Unit:1.Adopt high quality rubber vacuum belt, stocking and automatic input to ensure the efficiency of feeding.2. Special design makes the adjustment simply, quickly and precisely. The side regulation, paper feed baffle and belt are separately operated, which make the order change easy.Gluing Unit:1.The gluing width is 25mm/35 mm-gluing from bottom side.2.The glue box can be moved left or right according to the requirement of the corrugated board. 3.The gluing amount can be adjusted.4.The glue box is made of stainless steel-big contain and easy for cleaning.Folding Unit1.It uses high friction belt. The folding speed is controlled by frequency converter which can be controlled separately and synchronized with the main motor.2.Motor driven for order change adjustment-fast and convenient.3.Re-creasing roller, re-creasing knife, side roller and flapping plate can eliminate the fish tail effectively. Stacking and Counting Unit1.The Flapping Plate can help to reduce the fish tail phenomenon.2.The pile number can be set at 10, 15, 20 and 25. Electrical PartsScientific and reasonable mechanical structure, reliable quality electrical elements makes the machine free of trouble. Main Configurations: Electric Part:

| Name | Brand | Specification | Model | Quantity |

| Frequency converter | SHIHLIN | 3.7KW/2.2KW | 3.7VFD037EL43A 2.2VFB022EL43A | 1 |

| Power | Taiwan Mean Well | S-150-24 | NES-150-24 | 1 |

| Contactor | French Schneider | LC1-D0910M5C | LCE0910M5N | 5 |

| Control button | Shanghai Tianyi | Green button | LA42P-10 | 13 |

| Red button | LA42PD-01 | 1 |

| Green lamp | LA42PD-10/DC 24V | 4 |

| Red lamp | LA42PD-01/DC 24V | 4 |

| Yellow lamp | LA42PD-20/DC 24V | 1 |

| Control knob | Fuji | | LA42J-01 | 1 |

| Photoelectric switch | Omron | E3F3-D11 | E3F3-D11 | 1 |

| Air switch | Delixi | DZ47 | E3F3-D11 | 1 |

| Touch screen | Hitech | 190mm | PWS5610T-SB | 1 |

Automatic Bundling MachineSpecification & Carton Size Comparison TableSpecifications

| Model | JDB-1300A-T |

| Max Bundle Size | 1300*1200*250mm |

| Min Bundle Size | 430*350*50mm |

| PE Rope | 50# |

| Bundle Speed | 8-16 Packages /Min |

| Air Pressure | 0.4~0.8MPA |

| Power Supply | 3PH 380V |

| Main Power | 3.5kw |

| Dimension | 3900*2100*2100mm |

| Machine Weight | 2500KG |

Carton Size Comparison Table

| Note | Max | Mini |

| A | 1300mm | 430mm |

| B | 1200mm | 350mm |

| C | 250mm | 50mm |

Main Features1.High safety standard: The rope arm will be disengaged and come back to its start position when resistance is detected. The pusher will stop the machine if resistance is found. With the door open, the machine can not run. 2.Beak using Chromium-molybdenum alloy processed by a special procedures makes it more wear and tear with long service life.3.Driving gears are made of 45# steel dealt with high frequency heat treatment to increase its wear resistance.Other Features1.High efficiency, 8-16 bales per minute.2.Digital adjustment via touch screen easy to operate and understand.3.Digital adjustment via touch screen easy to operate and understand.4.Machine is equipped with automatic oil supply system which can lubricate the machine in time. Each input and output of electrical appliance is connected with monitoring points in touch screen to facilitate machine's maintenance. 5.Cost saving. PE only takes 0.17 Cents for one meter.Bundling unit1.Using pneumatic pressing structure, it makes the bundle tightness suitably and protect the paper pile effectively.2.Using 4 unique torsion control structures, combine with rope feeding arms to achieve protection functions. The arms will stop working if definite resistance happen between the arm and paper pile, this function will protect the operator and machine.3.Beak using Chromium-molybdenum alloy processed by a special procedures makes it more wear and tear with long service life.Lubrication systemMultiply points lubrication system provide oil into the machine, the oil will transport to the pre set position, the oil volume and frequency can be set. This function can effective protect the machine.Electric Part:

| Name | Brand | Specification | Model | Quantity |

| PLC-30 | | V-TH141T1 | | 1 |

| Contactor | Schneider | E-0901/E-0910 | | 11 |

| Button | TAYEE | IEC60947 | 24V | 7 |

| Photoelectric Switch | ORMON | E3F3-D11/E3Z-D61/E3FA-RN11 | | 4 |

| Air Switch | CHINT | DZ47-60 | C20 | 1 |

| Relay | Schneider | NR4 | 2.5-4A/0.63-1A/0.43-63A | 8 |

| Magnetic Valve | AIRTAC | 4V21008A | AC220V | 6 |

| Encoder | OMRON | E6B2-CWZ6C | | 2 |

| Touch Screen | HITECH | PWS5610T-S | | 1 |