Board Gluer Manual Die Cutting machine Machine

Overview Product Description The machine adopts leading edge feeding system, can complete the printing, slotting, angle-

Overview

Installation Instructions

Power source and air source connection : open the right side cabinet of slotting unit , the connect positions are shown in below picture . 2. The installation of folding gluing unit Connect the each structure of folder gluer unit , like below picture showing , there are 3 positions will be separated of the beam before loading. Please install the connection plate and tight the fixed screws.

3. Connect the wire of folder gluer unit.Like below picture showing, the wire and air pipe go through the upper beam from printer to folder gluer, the air pipe go into the cabinet of correction part. And the wire pipe go into the operate panel , connect by aviation sockets. (The number and type of plugs for each aviation socket in the electric control cabinet are different, and the connection is simple and convenient.)

4. Power source connection of folding gluing unit :like below picture showing , inside the back door of operate panel , connect the 3 phase 4 line power source .

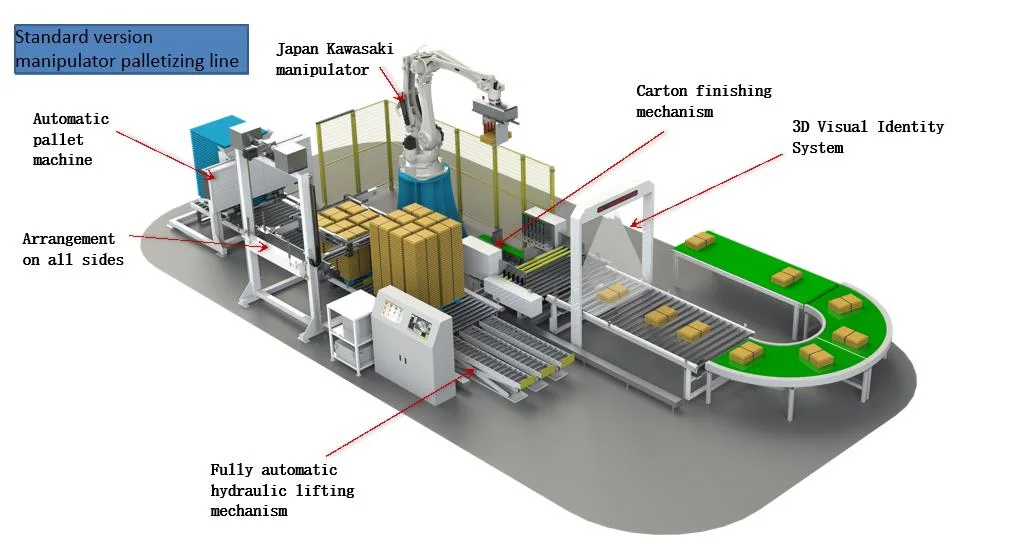

Recommend Products---Robot Palletizer &AGV forklift

2, Roller Conveyor

3, Automatic Laminator

4,Paper roll conveyor system

Company Profile

FAQ

Basic Info.

| Model NO. | GOJON-PDF |

| Function | Printer Die Cutter & Folder Gluer Linkage Line |

| Speed | 300PCS Mpm |

| Leading Time | 2-3 Months |

| Transport Package | Depends on Customers Requirement |

| Trademark | GOJON |

| Origin | Qingdao, China |

| HS Code | 84418090 |

| Production Capacity | 100 |

Product Description

Product DescriptionThe machine adopts leading edge feeding system, can complete the printing, slotting, angle-cutting, slitting, creasing, folding gluing etc. of corrugated paperboard in one time. Slotting depth of this machine is with computer and electric two types of adjustment methods, and equipped with the scale reading. Slotting phase adjustment is the planetary gear structure, adopting the computer 360 degrees adjustment, and the upper and lower slotting knife disc and creasing wheels can synchronous moving to left or right, it is easy to use and maintenance, compact, which is a professional in view of the small carton printing slotting forming equipment .

- Paper feeding roller adopts patterned roller, feeding roller pressure adopts eccentric wheel adjustment with left and right eccentric wheels, can adjust the pressure synchronously.

- Leading edge feeding department adopts vacuum adsorption device , make the feeding more smoothly, to avoid the slotting error to make upper paperboard misplace when feed paperboard, can fit to each kinds of paperboard with different quality , and sending paper stable and accurate.

- Slotting knife discs adopt full steel processed , slotting knives adopt sawtooth arc-shaped semicircle knives to slot and remove the waste, paperboard get into slitting roller after slotting, slitting knives cut both sides of the paperboard neatly . ( note : pressing wheel and slitting knives are installed in same roller, convenient to adjust.

- Paperboard is sent out by six transmission shafts after slotting, corner-cutting, creasing and slitting . This machine power is equipped with the frequency speed controller (speed is adjustable freely), adopting JTE frequency converter.

- This machine adopts electric planetary gear phase adjustment to adjust the paperboard size, can adjust without stopping.

| Model | 2200 |

| Design speed | 300 pcs/min |

| Economic speed | 200-250 pcs/min |

| The length of printing roller | 1800mm |

| Max feeding size (L×W) | 1800mm×600mm |

| Min feeding size (L×W) | 430mm×170mm |

| Min slotting interval | 135×50x90x80mm |

| Min height of box (H) | 70mm |

- The installation of printing unit

Power source and air source connection : open the right side cabinet of slotting unit , the connect positions are shown in below picture . 2. The installation of folding gluing unit Connect the each structure of folder gluer unit , like below picture showing , there are 3 positions will be separated of the beam before loading. Please install the connection plate and tight the fixed screws.

3. Connect the wire of folder gluer unit.Like below picture showing, the wire and air pipe go through the upper beam from printer to folder gluer, the air pipe go into the cabinet of correction part. And the wire pipe go into the operate panel , connect by aviation sockets. (The number and type of plugs for each aviation socket in the electric control cabinet are different, and the connection is simple and convenient.)

4. Power source connection of folding gluing unit :like below picture showing , inside the back door of operate panel , connect the 3 phase 4 line power source .

Recommend Products---Robot Palletizer &AGV forklift

Other main Products

1, Modular belt Conveyor2, Roller Conveyor

3, Automatic Laminator

4,Paper roll conveyor system

Company Profile

FAQ

| 1 | Do you have a minimum order quantity? | Yes, we require all international orders to have an ongoing minimum order quantity. But if you are looking to resell but in much smaller quantities, you can also contact us for further information |

| 2 | Can you supply the relevant documentation? | Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required. |

| 3 | What kinds of payment methods do you accept? | You can make the payment to our bank account, Western Union or PayPal:30% deposit in advance, 70% balance against the copy of B/L. |

| 4 | What is the product warranty? | We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone's satisfaction |

| 5 | How about the shipping fees? | The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information. |

previous:

AEM

Send to us