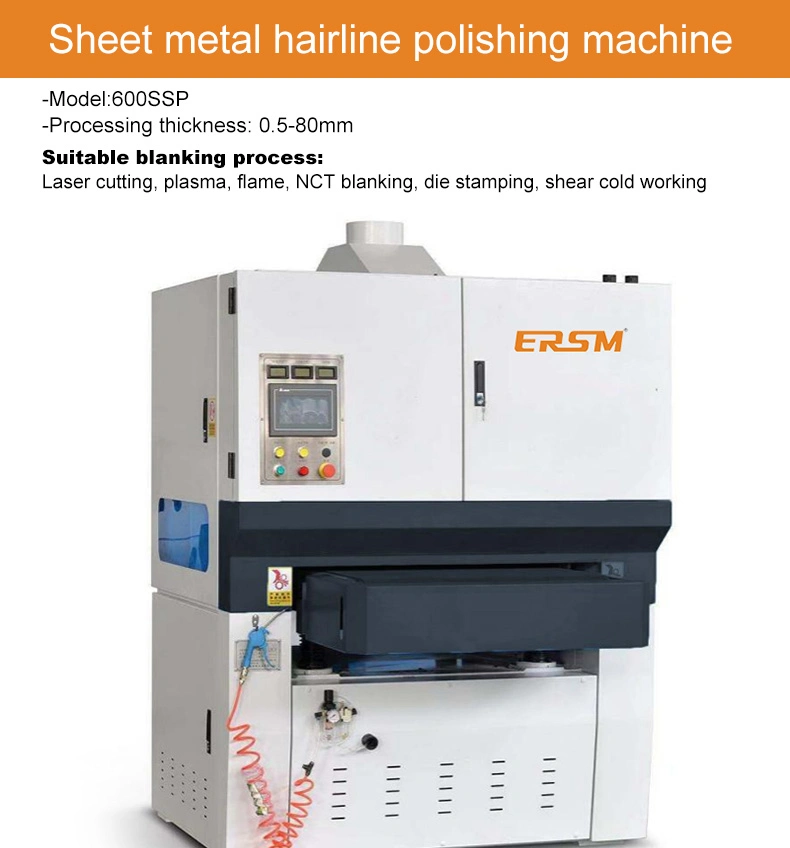

Stable for Laser Cutting Plasma Blanking Workpiece Sheet Metal Automatic Deburring Hairline Machine

Product Features 01. Suitable For Flat Plate Parts, Carbon Steel Plate, Stainless Steel Plate, Aluminum Plate, Copper Pl

Basic Info.

| Worktable Height | 900-980mm |

| Sand Belt Size | 1900*650mm |

| Power | 22kw |

| Weight | 2200kg |

| Voice | 86dB |

| Feeding Speed | 0.5-6m/Min |

| Minimum Processing Size | 300*300mm |

| Processing Thickness | 0.6-80mm |

| Processing Width | 600mm |

| Transport Package | Wooden Box |

| Trademark | ERSM |

| Origin | China |

| Production Capacity | 50sets/Month |

Product Description

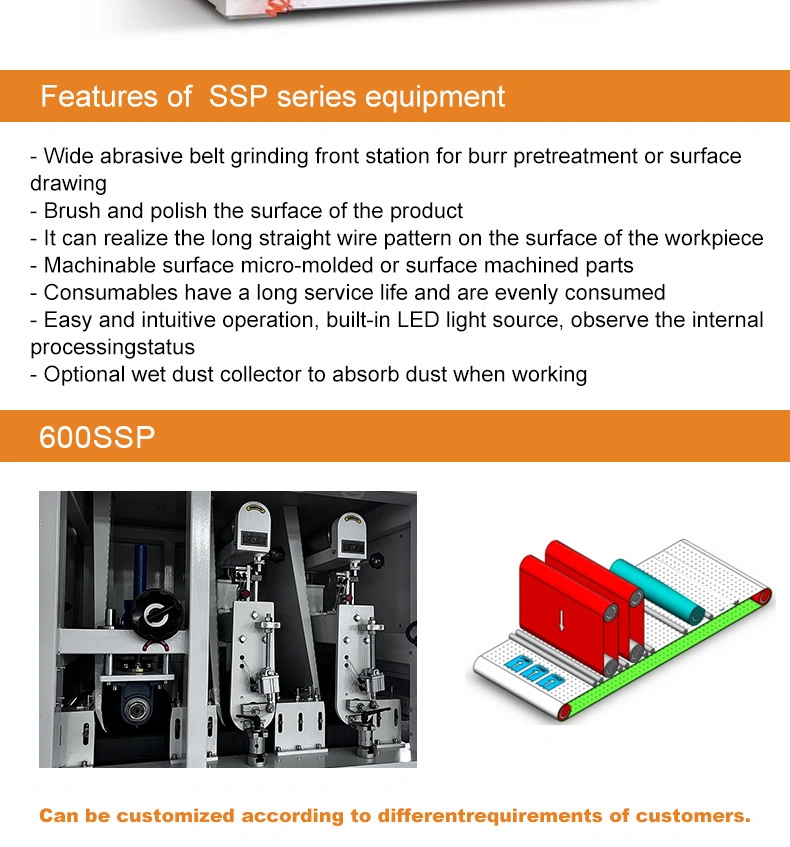

Product Features01. Suitable For Flat Plate Parts, Carbon Steel Plate, Stainless Steel Plate, Aluminum Plate, Copper Plate 02. Suitable for all kinds of flat plate parts surface drawing,polishing, scratch removal, removal of longitudinal burr, oxidation skin, fixed thickness and other processing 03.2 Sand Belt and 1 Polishing Roller04.Wet Dust Extraction05. Program storage function to achieve repeated processing result 06. Intuitive touchscreen HMI for easy operation 07. Optional feeding mode (1)Vacuum Negative Pressure Adsorption Conveying Feeding (2)Strong Permanent Magnet Adsorption Conveying Feeding (3)Conveyor Belt And Press Roller Feeding(Standard)

Product Parameter

| Model | 600SSP |

| Max Processing Width | 600mm |

| Processing Thickness | 0.6-80mm |

| Min Processing Size | 300*300mm |

| Feeding Speed | 0.5-6m/min |

| Worktable Height | 900-980mm |

| Sand Belt Size | 1900*650mm |

| Noise | ≤85dB |

| Dust Extraction Air Volume | 5000 cubic/h |

| Dust Extraction Efficiency | ≥85% |

| Rated Power | 22KW |

| Rated Voltage | AC 380V 50HZ |

| Machine Size | 2200*1300*2100mm |

| Weight | 2200kg |

FAQ

1. Who are we? A:We are based in Jiangsu, China, start from 2011,sell to Southeast Asia(20.00%),Eastern Europe(20.00%), WesternEurope(10.00%), North America(10.00%), Northern Europe(5.00%), Central America(5.00%),SouthAmerica(5.00%),Eastern Asia(5.00%),South Asia(5.00%),Oceania(5.00%),Southern Europe(5.00%),Africa(3.00%),MidEast(2.00%). There are total about 11-50 people in our office. 2.How long does it take for a machine to remove burrs? A: The time taken for the deburring process depends on the thickness and size of each sheet. A powerful machine can remove burrs quickly, but it requires skilled operators to safely. 3.When should I use a deburring machine?

A: Before finishing operations, you should use these machines for sharp metal objects that you want todeburr. This will increase the smoothness of the cutting operation and improve your end product. 4. What are the functions of the device? A: Suitable for flat plate parts,carbon steel plate,stainless steel plate,aluminum plate,copper plate,titanium alloy,allkinds of non-ferrous metals,rubber and plastic materials.Suitable for all kinds of flat plate parts surface drawing,polishing,scratch removal, removal of longitudinal burr, oxidation skin, fixed thickness and other processing. 5. How do we ensure the safety of workers? A: Matching wet vacuum cleaner to treat grinding dust to achieve environmental protection.

Send to us