Ecoographix Semi Automatic Foil Stamping Machine and Die Cutting Machine

Basic Info.

| Model NO. | ECOO-TDS 750L |

| Computerized | Computerized |

| Automatic Grade | Semi-Automatic |

| Application | Paper Packaging Materials, Cardboard |

| Max. Machine Speed | 2500(S/H) |

| Height of Cutting Rules | 23.8mm |

| The Thickness of Stamping Plate | 3.5mm |

| Max. Stamping Speed(S/H | 2500(S/H) |

| Min. Sheet Size | 280X220mm |

| Max. Sheet Size | 750X560mm |

| Max. Stamping Size | 700X500mm |

| Transport Package | by Sea in Wooden Case |

| Specification | 2600x1720x1975mm |

| Trademark | EcooGraphix |

| Origin | China |

| HS Code | 84414000 |

| Production Capacity | 500sets/Year |

Product Description

2500S/H Semi-Automatic Foil Stamping And Die Cutting Machine

Specification

| Model | ECOO-TDS 750L |

| Max. Sheet Size(mm) | 750x560 |

| Min. Sheet Size(mm) | 280x220 |

| Max. die cutting size(mm) | 700x500 |

| Max. stamping size(mm) | 700x500 |

| Height of cutting rules(mm) | 23.8 |

| Max. pressure(N) | 110x10 |

| Stock range | Min. Sheet 90g/m²; Cardboard 157-2000g/m²; E, B flute |

| Max. machine speed(s/h) | 2500 |

| Max. stamping speed(s/h) | 2500 |

| The thickness of stamping plate(mm) | 3.5 |

| Foil advancing shafts | 2 |

| Feeding pile height(mm) | 800 |

| Delivery pile height(mm) | 160 |

| Electric heating system | 4 zones |

| Min. foil width(mm) | 15 |

| Foil reel core(mm) | 25(1") 76(3") |

| Rated power(kw) | 40 |

| Air supply | 0.8-1.0 MPa, ≥ 0.6m/min |

| Overall dimension(mm) | 2600x1720x1975 |

| Weight of machine(kg) | 4200 |

Product Description

Brief Introduction:

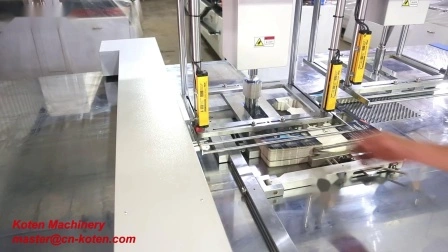

TDS750L cardboard die cutting machine is designed for the hot stamping, die cutting, pressing convex and creasing etc techniques, it is suitable for paper, cardboard, plastic file and so on. It can finish feeding, die cutting separating collecting work cycle automatically. Most of factory owners rather choose cardboard die cutting machine. They were attracted by economical, smart, easy to change plates and other features of this model. We will support installation and training for new customer for free (labor cost).Excellent adaptability and convenient operation make the machine work stably and safely. Automatic hot foil stamping machine will provide you with comfortable operation and a faster return on investment.

The TDS750 is especially suitable for customers with short working hours but high production demands because of its faster conversion system and smarter design. In so many years of sales, the automatic hot stamping machine TDS750 is still one of our best-selling products with its ingenious design. Many customers with lower budgets are very interested in this machine.

Machine Spare Parts List

1. Delivers accurate, adjustable impression for foil stamping, embossing and die cutting2. Two horizontal, cross pull foil feeds are fully programmable to provide maximum versatility and excellent foil economy3. Air blast system helps separate foil from stock on critical jobs4. Micrometer adjustment on side guide and front guide5. Adjustable dwell on impression6. Honeycomb base is convenient for loading7. Missed sheet detector8. 4 heating zones with digital control9. 24 hours preheating device10. Control system with touch screen HMI, PLC and servo system.

More Details

FAQ

Q: What about the Installation and after-sales technician support?

A: Our engineer can go to help the installation and provide the necessary training. The buyer should take the round air plane tickets and service charge and the local accommodation cost. Any problems or questions, we will be at your disposal 7x24 hours.Among our large amount of CTP installations worldwide, there are also many end users (printers) who have purchased the CTP products from EcooGraphix China directly and EcooGraphix technical service team support these installations remotely with regular onsite visits. These end users Printers all run the CTP systems with full satisfaction due to our robust quality, seamless remote service, thorough training and maintanence. If you are a printer who is considering purchasing directly from EcooGraphix China, there is no hasle on installations, training and after sales service. We guarantee your satisfaction.